Torch-On Roofing vs Other Flat Roof Systems

Flat roofs in Vancouver don’t all play by the same rules. Torch-on, TPO, and EPDM are three different ways of solving the same problem—keep water out on a low-slope roof—but they do it with very different personalities. If you’re staring at a quote with a bunch of acronyms on it, this is what’s actually going on behind those letters.

Torch-On vs TPO Roofing

Think of torch-on as the heavyweight boxer and TPO as the lean endurance athlete. Both can win, but in different rings.

Torch-on (SBS-modified bitumen) is a thick, layered system: a base sheet plus a cap sheet, fused together with controlled heat. It gives you a dense, multi-layer membrane with welded seams and a bit of “give,” so it can handle foot traffic, small movement, and the kind of day-to-day abuse that happens on low-slope roofs near the coast. If someone drags a ladder across it or a tradesperson drops a tool, torch-on has a decent margin for forgiveness.

TPO is a single-ply thermoplastic membrane. Instead of layering bitumen, you have one sheet of material, heat-welded at the seams. Its biggest visible advantage? Reflectivity. TPO membranes are often light-coloured and highly reflective, which can help with heat gain on big commercial roofs. On large-box stores and sprawling warehouses, that’s a real operational benefit.

Durability-wise, both can be strong systems when installed properly. The differences show up in:

- Repairability – Torch-on can be patched locally with more torch-on, fusing new material into the existing assembly. TPO can be repaired too, but it’s more finicky about surface cleanliness, weather, and technique.

- Detailing – Torch-on is extremely good at wrapping tight corners, complex parapets, and odd transitions. TPO can handle details as well, but often needs pre-formed accessories or very precise workmanship.

- Cost – On smaller to medium roofs, torch-on is often more cost-effective. TPO’s advantages tend to shine on larger commercial footprints where energy savings and material economies of scale come into play.

If you’ve got a Vancouver garage, laneway home, townhouse carport, or compact commercial roof, torch-on usually feels like the more “down-to-earth” workhorse. TPO often steps in for big, clean commercial roofs where reflectivity and long runs of membrane are the priority.

Torch-On vs EPDM Roofing

EPDM is the veteran of the flat-roof world—a rubber membrane that’s been used for decades, especially in industrial and commercial settings. When you put torch-on beside EPDM, a few big differences jump out.

First, seam technology. Torch-on relies on seams that are thermally bonded between layers of SBS-modified bitumen. You get a full, welded assembly that—when done right—behaves like one continuous waterproof layer.

EPDM traditionally uses taped or glued seams. Modern seam tapes are far better than the old-school glues, but you’re still dealing with adhesive-based joints that depend heavily on prep and long-term adhesion. If a seam fails on EPDM, it’s usually because that bond has broken down under UV, movement, or water exposure.

Then there’s flexibility and handling. EPDM is a large, flexible rubber sheet that can be rolled out in big sections with very few seams on wide, open roofs. That’s its superpower. On a big warehouse, that simplicity can be a major advantage.

Torch-on’s strength shows up in complex detailing and multi-layer resilience. It can climb walls, wrap edges, tuck into parapets, and create multi-ply reinforcement at problem areas. When you have lots of penetrations (vents, skylights, mechanical curbs) or tight parapet conditions, torch-on often gives more confidence at those intersections.

Use cases in a nutshell:

- EPDM: great for big industrial roofs with simple layouts, long runs, and minimal clutter.

- Torch-on: excels on more compact roofs, mixed-use buildings, and any scenario where drains, parapets, and intricate edges are the main threat.

When Torch-On Is the Best Choice in Vancouver

In Vancouver’s climate, torch-on becomes the default answer more often than not for small and mid-sized flat roofs. Here’s why.

You’ve got constant rain, recurring freeze-thaw near the shoulders of winter, moss growth, and roofs that are rarely as simple as the drawings made them look. Drains get clogged, leaves pile into corners, and parapets and balcony details end up doing a lot of the heavy lifting. In that environment, you want a system that:

- Handles constant wetting and drying without giving up at the seams

- Can be patched, overlaid, or reinforced without tearing everything back to zero

- Wraps parapets, scuppers, internal drains, and transitions without relying solely on glued accessories

- Stands up to occasional foot traffic from trades, owners, and maintenance crews

Torch-on tends to shine on:

- Small and medium flat roofs – garages, additions, laneway homes, smaller commercial units

- Townhouse and strata sections – carports, walkway roofs, amenity structures, low-slope blocks

- Mixed roofs – where a shingle or metal main roof ties into flat sections that need real waterproofing, not improvisation

If you want a deeper technical breakdown of how torch-on stacks up against TPO and EPDM specifically in Vancouver’s climate, the most direct resource to study is the comparison on our site here: Comparing torch-on, TPO, and EPDM for low-slope roofs in Vancouver.

Roofing Systems We Recommend for Vancouver’s Climate

Vancouver’s weather punishes weak materials. Months of rain, heavy snowloads, swirling coastal winds, and constant moisture mean your roof system has to do more than “look good”—it has to perform under pressure. The systems we recommend aren’t based on hype; they’re based on what survives long-term on the West Coast, especially in neighbourhoods with dense trees, north-facing slopes, and older framing.

Architectural Asphalt Shingles for Most Vancouver Homes

For the majority of Vancouver homes, architectural asphalt shingles strike the best balance between durability, cost, and coastal performance. They handle heavy rain well, resist algae growth better than older 3-tab products, and offer solid wind protection when nailed properly. For houses in East Van, Burnaby, or tree-heavy North Shore streets, shingles with strong algae-resistant coatings and robust underlayment pair perfectly with our damp climate.

They also absorb sound better than metal, which helps during Vancouver’s heavy rainfalls. Installed correctly—with clean valleys, proper flashing, and enough ventilation—they’re often the most practical solution for long-term reliability.

Standing Seam Metal Roofing for Long-Term Performance

When you’re planning to stay in a home for decades—or want a zero-maintenance option—standing seam metal is hard to beat. It sheds rain immediately, shrugs off moss, and stands strong in high-wind zones like False Creek, UBC, or waterfront areas where gusts funnel between buildings. Metal also performs exceptionally well on lower pitches where asphalt can struggle.

It’s a higher investment upfront but often the last roof you’ll need. For homeowners comparing materials, our page on metal roofing in Vancouver goes deeper into the benefits and long-term value of switching to steel or aluminum panels.

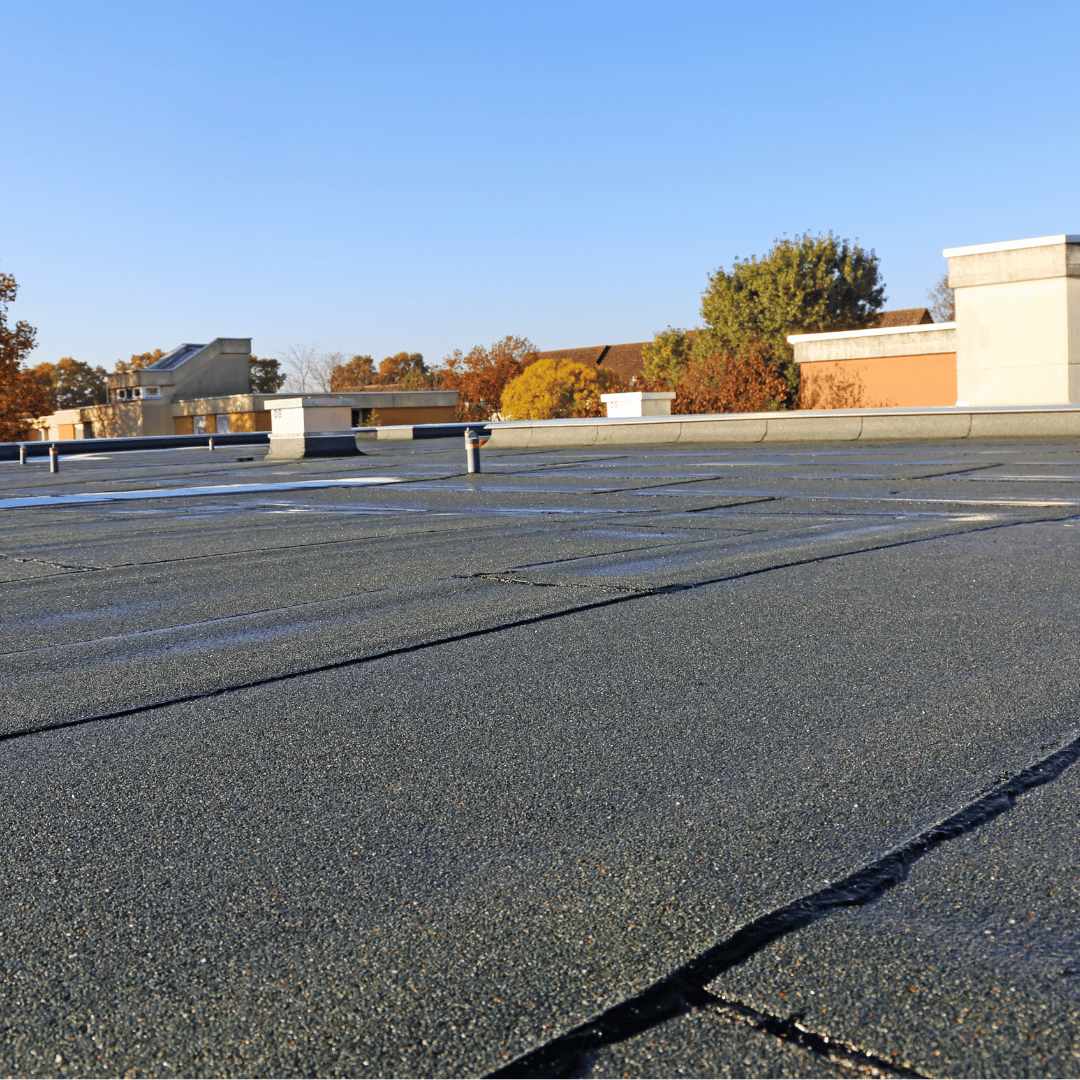

Flat & Low-Slope Roofing (Torch-On, TPO, and More)

Many Vancouver homes—especially additions, rear extensions, and older character houses—have mixed pitches with low-slope sections. These areas need systems designed to handle standing water and slow drainage. Torch-on (SBS) remains the workhorse for residential low-slope in BC, while TPO and PVC shine in certain commercial or multi-family applications.

What matters most is detailing: drains, scuppers, wall transitions, parapets, mechanical penetrations, and proper slope. A good low-slope roof isn’t just a membrane; it’s a collection of details that all have to be done right.

Cedar Conversion Options for Aging Shake Roofs

Thousands of Vancouver homes were built with cedar shake, and many of those roofs are now at the end of their lifespan. Converting from cedar to asphalt or synthetic shingles requires more than a simple re-roof—it often includes new sheathing, updated ventilation, and modern flashing that older homes never had.

A proper cedar conversion transforms an old, uneven deck into a modern, watertight system with cleaner lines, better airflow, and far less maintenance. For homeowners weighing replacement options, our cedar conversion service outlines how the transition works from start to finish.

Ventilation, Insulation & Ice-Dam Prevention in Local Conditions

In Vancouver, the roof system isn’t just the exterior—it’s the attic beneath it. Poor ventilation traps moisture in winter and heat in summer, leading to early shingle failure, mould, condensation, and ice dams in colder pockets of the Lower Mainland. Modern roofing means balancing exhaust vents, intake vents, and insulation so the roof can dry out properly between storms.

A well-ventilated system lasts exponentially longer here. It also reduces moss growth, improves indoor comfort, and dramatically cuts the risk of hidden sheathing rot.

How Much Does a New Roof Cost in Vancouver?

Roofing prices in Vancouver aren’t random—they’re tied to the city’s weather patterns, building styles, access challenges, and the complexity of older neighbourhood homes. Two roofs can have the same square footage but wildly different quotes depending on pitch, number of layers, ventilation upgrades, and how much plywood repair is needed under the surface. Understanding what drives cost gives you control over the process long before the first crew arrives.

Key Factors That Drive Vancouver Roof Pricing

Several elements shape the final number on a roofing quote:

• Roof pitch and complexity

• Tear-off difficulty (1 layer vs 2–3 layers)

• Decking condition and plywood replacement

• Flashing work around skylights, walls, and chimneys

• Ventilation and insulation requirements

• Material choice (asphalt, metal, cedar, synthetic, torch-on)

• Access for disposal bins and crew movement

• Weather considerations and protection requirements

The goal isn’t just to compare prices—it’s to compare what’s actually included.

Typical Cost Ranges by Roof Type & Complexity

As a rough structure, simple gable roofs with architectural shingles sit at the lower end, while multi-gable, steep, or complex homes with skylights, dormers, or multiple transitions move into higher ranges. Metal, cedar, and synthetic options increase investment but extend lifespan significantly. Low-slope systems also vary depending on whether the project needs slope correction, insulation, or detailed flashing work.

Ranges matter, but understanding your specific home matters more—it’s why on-roof inspections are essential.

How Roof Size, Access & Height Affect Your Quote

A small roof at 35 feet of height can cost more than a larger roof at 20 feet. Height dictates safety planning, equipment, and labour speed. Access also matters: tight Vancouver lots, alley-only access, and limited bin placement all impact labour time and disposal costs.

The easiest roofs to replace are open, low, and accessible. The hardest? Tall, steep, tree-covered, or in neighbourhoods with restricted parking and staging. Your quote reflects the reality of working on that specific structure.

Financing, Phased Work & Budget-Friendly Options

Not all Vancouver roofing projects need to be paid in one shot. Staged work—such as handling the most urgent section first or upgrading ventilation before full replacement—can extend the roof’s life until you’re ready for a complete project. Some homeowners also choose to finance the job to spread payments out instead of absorbing the full cost during a single season.

We also offer budget-conscious pathways like using architectural shingles instead of premium synthetics, or timing the project during slower periods. The key is matching your roof’s condition to a realistic, manageable plan so you stay protected without financial strain.